Te contamos qué puntos incluye la logística inbound dentro de un almacén y por qué es importante tenerla en cuenta para tu negocio.

Lograr un funcionamiento más eficiente, ahorrar costes económicos y mejorar la calidad del trabajo de los empleados. Estos 3 son los objetivos que va a lograr una buena estrategia de inbound logistics.

Una estrategia que, a su vez, tiene que tener en cuenta la logística outbound, de manera que vayan de la mano y la experiencia del cliente final sea la mejor posible.

La optimización inbound es, por tanto, uno de los factores que siempre hay que tener muy presente en cualquier empresa donde el almacén sea el motor del negocio.

Hoy te contamos qué es exactamente la logística inbound, cuáles son las diferencias entre inbound y outbound y cuáles son las fases de la logística inbound, para que puedas controlar y mejorar cada uno de esos pasos en tu negocio y así lograr que la logística outbound comience de la mejor manera posible.

¿Qué es la logística Inbound?

La logística inbound es aquella que comienza con la llegada de los productos que necesitamos para después enviar lo que el cliente necesita. Es decir, comienza con la recepción del pedido que ha hecho nuestra empresa y termina cuando se almacena y registra.

En ocasiones serán productos finales que nuestra empresa almacenará porque somos distribuidores (intermediarios) y, en otras, serán materias primas que necesitamos para elaborar nuestros propios productos.

De una buena ejecución del proceso de inbound logistics depende que:

- Los productos se almacenen y se registren lo antes posible y sin errores. Es decir, que tengamos al día nuestra base de datos para saber si necesitamos hacer nuevos encargos, si tenemos stock suficiente y tomar mejores decisiones para nuestro negocio. Para ello, también necesitaremos un buen software de SGA.

- Sepamos si disponemos de materiales suficientes para seguir con la fabricación de los productos de la empresa. De ahí la importancia de registrar lo antes posible las mercancías que llegan a nuestro almacén.

- Que los pedidos de los clientes salgan lo antes posible. Porque gracias al picking, sabremos de cuántos disponemos y dónde están para ir directamente a buscarlos.

Es justo en este último punto donde entra en juego el outbound logistics. Otra estrategia que, aunque va de la mano con la inbound, es diferente.

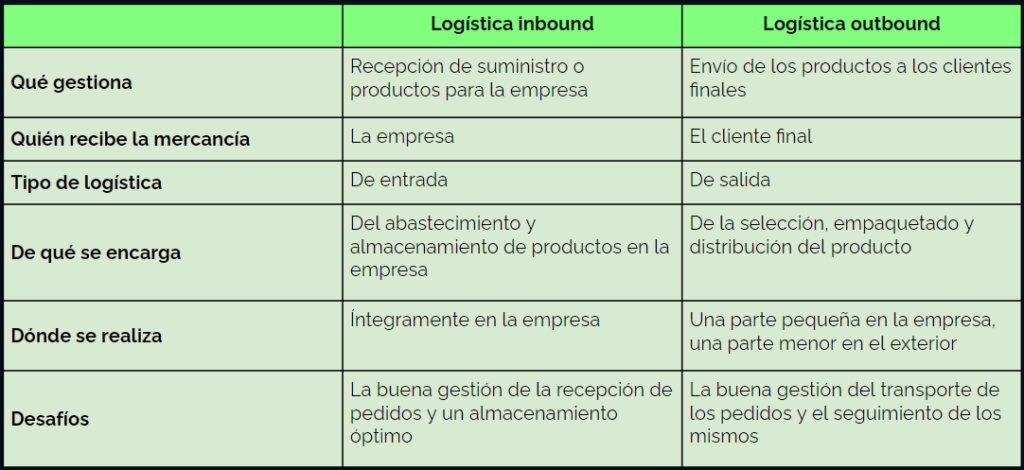

Diferencias entre logística Inbound y Outbound

Ahora que ya sabes el significado de la logística inbound, vamos a pasar a hablar las diferencias entre inbound y outbound logística:

Fases de la logística inbound

Para poder revisar si la estrategia inbound logistics de tu negocio es correcta o necesitas ayuda para mejorarla, estos son los puntos que debe seguir el proceso:

Pedidos de entrada

Es la fase más importante de todas, porque es aquella en la que nos encargamos de recibir el pedido que ha hecho la empresa para poder seguir con su trabajo del día a día. En este punto es importante:

- Fijar plazos de entrega con los proveedores. Porque de ellos depende que no haya rotura de stock en nuestro almacén y que podamos lograr el compromiso que hemos adquirido con nuestros clientes.

- Reducir costes de transporte con la empresa que se encarga de traernos esos materiales. Podemos negociar tarifas o hacer que los pedidos nos lleguen en un mismo día por parte de un proveedor, en lugar de pedirle cada poco tiempo.

- Anotar bien las fechas de entrada de esos pedidos. Sobre todo si trabajamos con productos perecederos o que se pueden estropear con el paso del tiempo, pero también porque forma parte del correcto registro de datos de la empresa y de la previsión de nuevos pedidos para responder a la demanda de nuestros clientes.

Gestión de la entrada

Es decir, que podamos controlar que tenemos el espacio suficiente en la empresa para poder recibir a los transportistas y que no estén esperando más tiempo del necesario. En ocasiones, esa gestión de entrada también estará relacionada con el apartado burocrático relacionado con pedir permisos especiales para la llegada de ciertos tipos de transporte o de maniobras, especialmente si nuestro almacén se encuentra en un lugar muy transitado o de difícil acceso.

Descarga y calidad

Nuestro proveedor se encargará de que los productos lleguen a nuestra empresa en perfectas condiciones, pero una vez los recibimos, es parte de la logística inbound hacer todo lo necesario para que los productos lleguen en perfectas condiciones a nuestro almacén, además de pasar por los controles de calidad que tengamos establecidos, de manera que no nos llevemos sorpresas en la empresa.

Todo el proceso debe de estar perfectamente cumplimentado y los operarios han de conocer todos los pasos. En este punto, también es importante que contemos con las soluciones logísticas que nos van a permitir que el tiempo que se tarda entre que se descarga el producto y se almacena, sea el más eficiente posible, puesto que de esto también dependen los ingresos del negocio.

Picking y ubicación de stock

El último paso y el más importante. Para ello, hay que tener una previsión de espacio en nuestro almacén, de manera que ya sepamos de antemano dónde vamos a ubicar ese producto, teniendo en cuenta el uso que le vamos a dar en la empresa en caso de que sirva para fabricar un producto o la periodicidad con la que se pide por parte del cliente final, en el caso de que sea un producto ya fabricado, para que los que más se demandan, estén situados más cerca de la salida.

Una vez sabemos dónde los vamos a colocar, solo nos queda registrarlos mediante un sistema de picking y que éste, a su vez, esté unido a un software de gestión de almacén que nos pueda dar información real al instante.

Cada uno de estos pasos debe estar perfectamente planificado y cada tarea asignada a una o varias personas de la empresa.

Conclusión

Como ves, tener una adecuada gestión del inbound logistics nos ayudará a tener una mejor previsión de productos o materias primas para nuestro negocio, cuidarlos al máximo, tenerlos 100% controlados dentro de nuestro almacén y tomar mejores decisiones para la empresa.